Factories

Show what you make.

PaperTale makes it possible for factories to in real time showcase what they make, increasing trust and giving them the possibility to become a factory of the future. We want to increase incentives by enabling factories to gain more power and showcasing the necessary work and the true cost of becoming more sustainable. We believe that the more transparent factories are and the more they increase sustainable practices, the more power and earning they should get.

How it works.

By integrating PaperTale into existing systems, factories can gather and showcase the flow of material, the real time social and environmental data and how it has been verified. All of this work done by the factory will be showcased in the PaperTale system, and made accessible in our Consumer App, making it possible for brands and consumers to follow the entire journey of a product and the people who were a part of creating it.

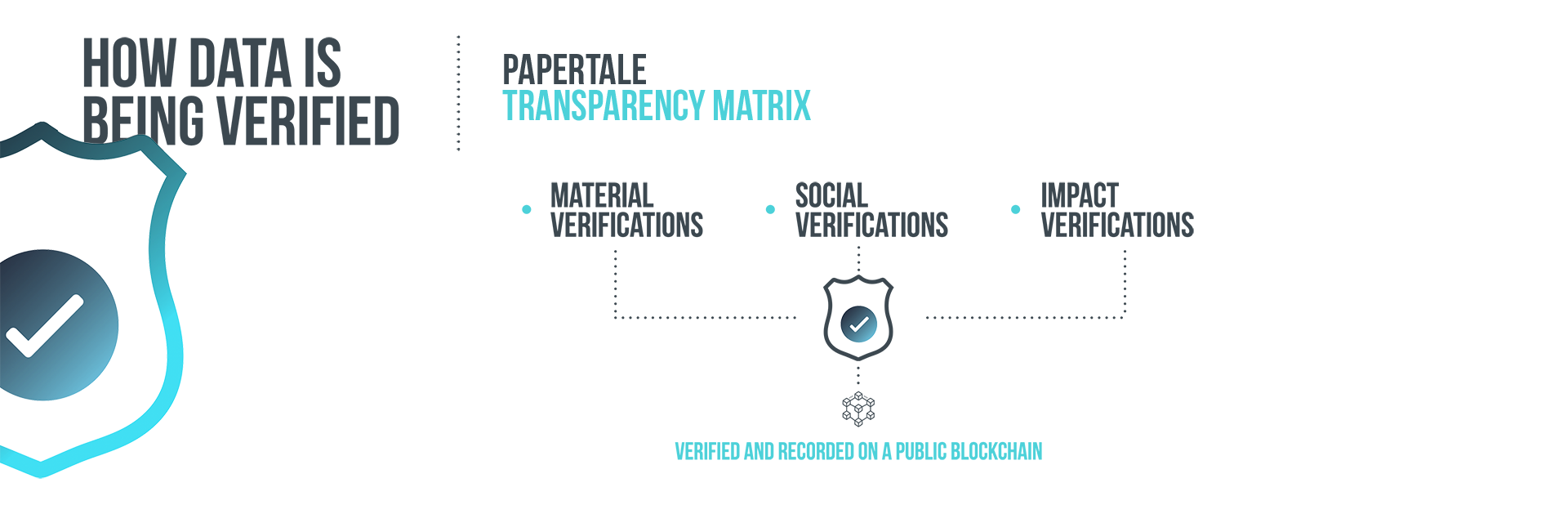

Material verification is how the physical material is gathered and verified by the factory. With PaperTale’s system, it is possible to showcase the material composition of a product and the origins of these materials.The system also allows factories to show the verifications they have used for this information, such as verification from material buyers and suppliers, internal and external lab tests or audits, and the use of physical trackers like NFC tags.

Social verification is all about conducting and showing actions that ensure a fair and safe environment for the craftsmen. The PaperTale system makes it possible to gather and verify workers’ contracts and wages, assessments of workplace and building safety, overtime approvals, and if the factory has a profit sharing system. In this way it is ensured that no child labour is being used, wages are being paid according to law, the craftsmen are working in a safe environment and that they are getting paid for their overtime hours.

The environmental impact verification is about showcasing the environmental impact of a product. With the PaperTale system it’s possible for the factory to gather the environmental impact of a product using data from their facility, LCAs or other external research, or from the usage of sensors (IoT), which gather the data in real time. This makes it possible to get a full view of a product’s environmental impact by combining the environmental impact from the sourcing of materials, factory production and transportation.